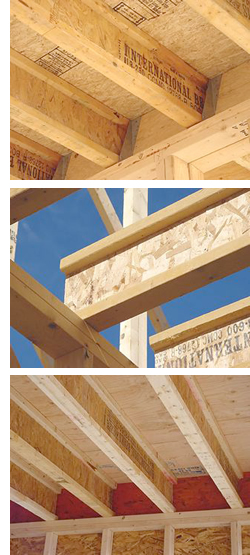

Engineered Wood products, and specifically I-Joist, offer advantages over conventional lumber products that result in savings for the builder and long-term performance benefits for the homeowner. Engineered Wood products, and specifically I-Joist, offer advantages over conventional lumber products that result in savings for the builder and long-term performance benefits for the homeowner.

I-Joist are installed using traditional framing tools and fasteners. With long lengths, I-Joist are used in multiple span applications, therefore reducing cutting, overlapping, and material waste on jobsite.

LVL (Laminated Veneer Lumber) are ideal for floor beams, garage door headers, window and door headers, and ridge and hip beams. They deliver solutions where construction design calls for long unsupported spans.

Engineered Wood Features and Benefits:

- STRUCTURALLY SUPERIOR TO CONVENTIONAL FRAMING.

- COMPATIBLE

WITH CONVENTIONAL CONSTRUCTION HARDWARE AND FRAMING METHODS.

- DIMENSIONALLY CONSISTENT.

- CONSTRUCTED OF KILN-DRIED LUMBER WHICH ELIMINATES SHRINKAGE,

WARPING, TWISTING AND SPLITTING.

- CONSTRUCTED OF RE-CONSTITUTED LUMBER HARVESTED FROM SECOND-GROWTH

FORESTS RATHER THAN 200 TO 300 YEAR OLD GROWTH FROM WHICH 2x10s

AND 1x12s ARE TYPICALLY CUT.

- UTILIZES 40% LESS WOOD THAN CONVENTIONAL FRAMING METHODS.

- COMPUTERIZED LAYOUT FROM STATE-OF-THE-ART SOFTWARE THAT

ENSURES THE MOST ECONOMICAL BUT COMPLETE SPECIFICATIONS

OF ALL REQUIRED COMPONENTS.

- WARRANTED TO BE FREE FROM DEFECTS.

- LIGHTER THAN CONVENTIONAL FRAMING,

DECREASING INSTALLATION TIME.

- LOAD CAPACTIES ARE DETERMINED FROM TEST PROCEDURES AND

APPROVED BY STRUCTURAL ENGINEERS.

- CONTINUAL QUALITY CONTROL MEASURES IMPLEMENTED INTO

THE MANUFACTURING PROCESS.

- DESIGN AND MANUFACTURED TO FIT EACH JOB REDUCING SITE

AND MATERIAL WASTE.

These I-Joist framing members can provide a solid, quiet,

and cost affective floor or roof system while reducing framing

time and lowering your total job cost.

|